- (716) 839-0900

- info@stcsoundcontrol.com

Menu

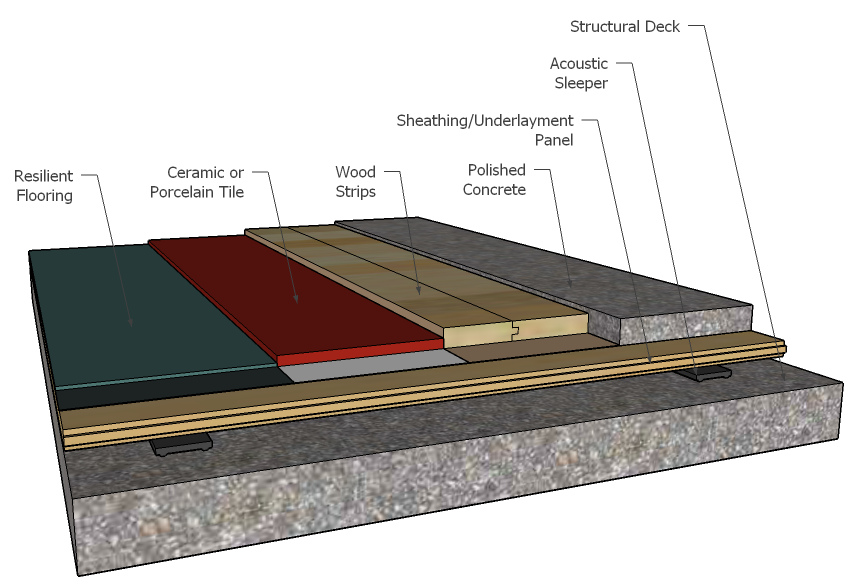

Noise from floors above can travel through the floor structure and radiate into the space below. This is known as impact noise or footfalls, which is measured by a standard called the Impact Insulation Classification (IIC). Different elements of the floor and ceiling construction contribute to isolating this noise in various amounts, and are called the ΔIIC, or Delta IIC (for difference). Acoustic sleeper strips are recommended at terminal edges and butt-edges of panels. Use acoustic sleeper pads in the field of panels and at tongue-in-groove edges.

SUSTAINABILITY: Floor decks composed of wood panels and the STC Acoustic Sleeper neoprene pads have a carbon emissions rate that is 350 times less than decks made of gypsum cement and acoustical mats, 50 times less than decks with rubber mats, and 20 times less than decks with recycled rubber mats. The main factors are the carbon emission rates of gypsum cement compared to wood panels, and the size of rubber mats compared to pads. Also, wood is renewable, which is much more sustainable than even recycled gypsum or recycled rubber.

COMFORT: Shin splints, known as “medial tibial stress,” are shins that ache, and result from footfalls on hard surfaces. Wooden floors are much more comfortable than concrete or gypsum cement because of their resilience, and are much less likely to cause shin splints.

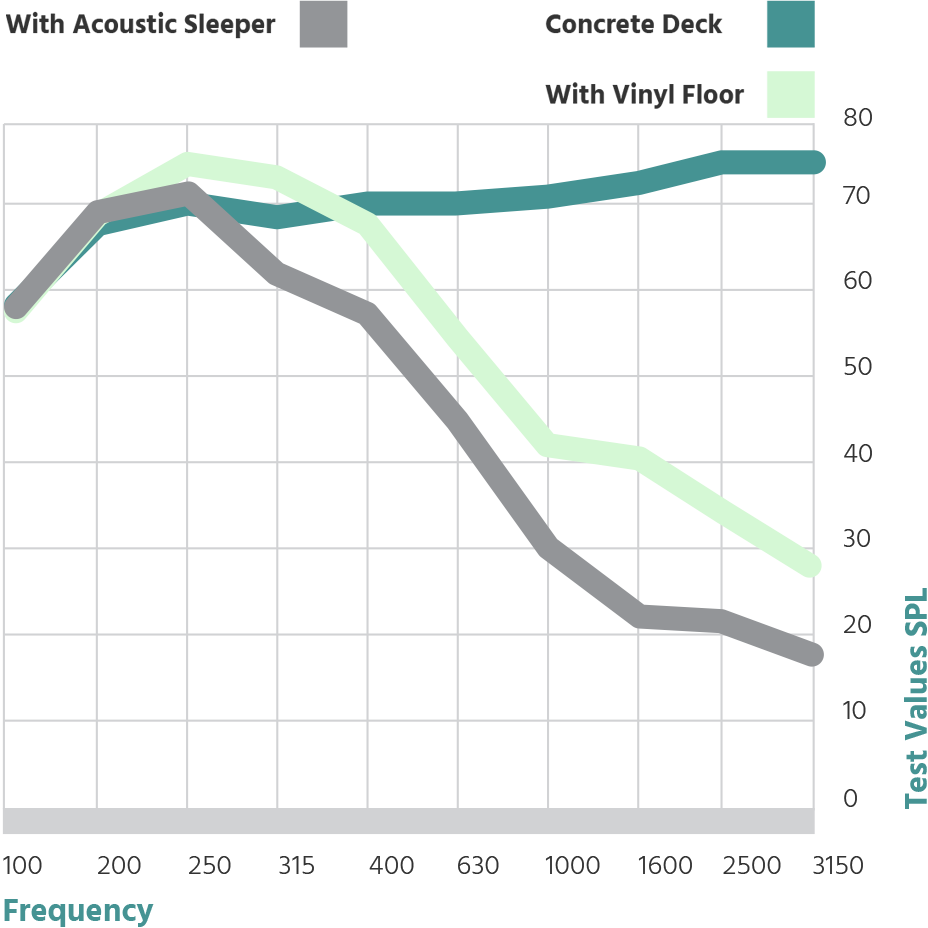

The Acoustic Sleeper system has a ΔIIC-23, a higher impact insulation classification than acoustical mats and gypsum cement, rubber mats, cellulose panels, and cork. The Acoustic Sleeper pads or strips are paired with a construction panel that has a structural span rating and forms the subfloor such as oriented-strand board (OSB), plywood, cement-bonded particle board, structural cement or magnesia board.

The Acoustic Sleeper allows installation of any type of finish flooring, including hardwood strips, engineered wood, tile (stone, porcelain, ceramic, glass), LVT, vinyl sheet, vinyl plank, vinyl tile, rubber flooring, carpet tile, broadloom carpet or even thin lightweight concrete.

Wood frame construction typically has a single subfloor/sheathing panel. The Acoustic Sleeper system separates the functions with two panels. The sheathing panel is fastened to the structural members to provide diaphragmatic shear resistance. The subfloor panel is supported on top of the sheathing by the Acoustic Sleeper pads or strips, and in line with the structural members. This isolates the transmission of impact vibration while transferring the live loads to the structure. In event of fire, the lower sheathing layer chars and protects the upper subfloor layer so it can continue to carry the structural loads for the required fire resistance. Current UL Designs include:

Non-combustible construction also has a subfloor panel supported on top of the deck by the Acoustic Sleeper pads or strips. It not only provides an exceptional Impact Insulation Classification for footfalls; it also provides isolation from other structure-borne sounds between floors.

Building codes require that fire partitions extend from the top of a fire-rated floor/ceiling assembly (IBC 708.4). The Acoustic Sleeper system is an integral part of 2-hour fire-rated UL Design D902, so instead of extending from the concrete deck, partitions can by placed on top of the panels – they are part of the assembly. This provides a break in the sound flanking path that normally sends noise from televisions or speakers mounted on the partition or floor through the studs and concrete to apartments above and below.

The Acoustic Sleeper can be used in a variety of environments where floor noise is a concern and impact insulation the goal

The Acoustic Sleeper has a number of benefits over competitive products

The Acoustic Sleeper is ultimately effective because it creates structural discontinuity. The goal of noise isolation is to keep the material that receives the impact from contacting the actual building structure.

The profile (patent pending) and spacing of the sleepers creates a huge difference between the amount of finish floor area and the amount actually in contact with the structure. For sleeper pads spaced at 24 inches, this means 99.7% of the finish floor area actually floats above the structure, making them superior to options like mats that make continuous contact with the structure.

Section 061600 “Sheathing” as an Acoustical Accessory for Underlayment Systems, under Miscellaneous Materials.

Buffalo, NY 14215

Telephone: 716-839-0900

E-mail: info@stcsoundcontrol.com

STC Sound Control makes acoustical products for architecture that minimize the annoyance and aggravation related to noise…..read more